Which Grease Trap Should I Choose?

This information is a non-technical guide for anyone unfamiliar with how grease traps operate. It is for guidance only, for more information please contact Mactrap.

In New Zealand there are 3 main types of grease traps: Gravity Grease Traps, Grease Removal Units and Grease Converters. Within each of these types there are multiple sizes and features to suit particular applications.

Choosing which one is best suited to your premises will depend on your local council requirements, the space you have, your access constraints, and your budget.

Passive Grease Traps

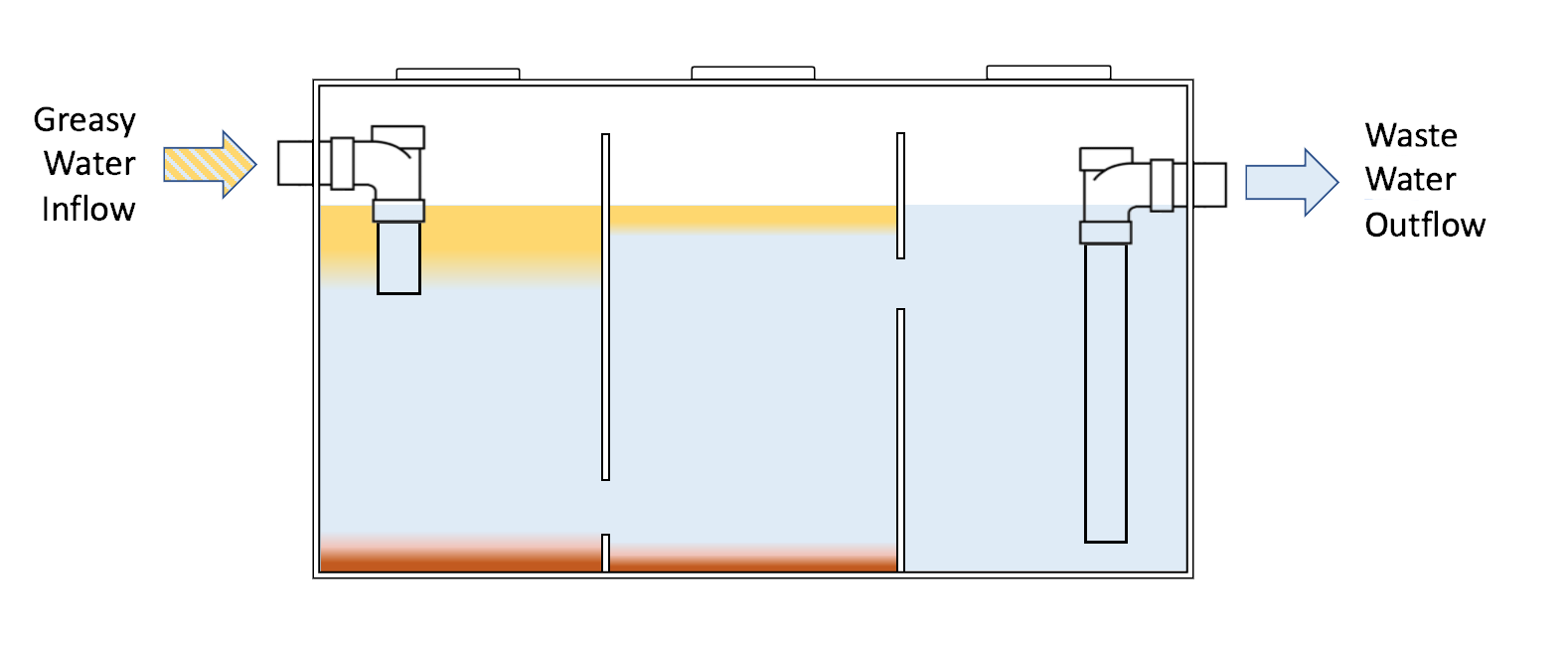

Passive grease traps (MACTRAP Grease Traps) are large tanks, designed to hold and slow the flow of wastewater so that the Fat, Oil and Grease (FOG) can separate and be prevented from entering the Councils wastewater network. The passive grease trap has baffles which slow the flow of waste water from kitchen sinks or other kitchen waste water outlets. This slowing process allows the FOG to rise to the surface, heavier food scraps and sediment to sink to the bottom, and the cleaner separated water to flow out of the trap and into the wastewater system. Over time the FOG builds up (along with sediments) and the trap has to be emptied by a professional tank cleaning agent.

Passive grease traps are usually installed externally and near the kitchen drains. Passive grease traps offer the lowest maintenance effort for kitchen staff, and for this reason Local Government Authorities prefer this system. MACTRAP passive grease traps are made from a high density polyethylene and can be installed above or below ground as their structure does not need the support of surrounding earthworks to keep them in shape.

Considerations

Grease Removal Units

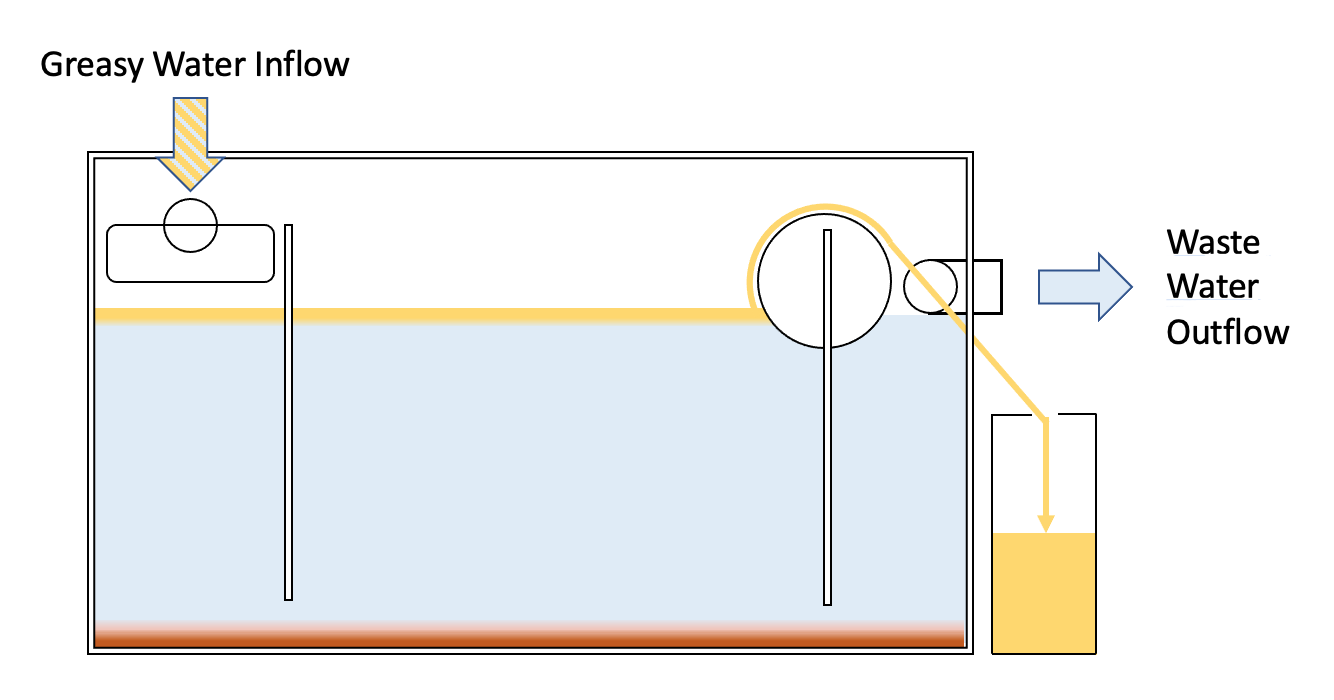

Grease Removal Units (MACTRAP Grease Boss EasyClean) are usually installed internally, under a bench, and close to the sink where the wastewater containing FOG comes from. They are made from stainless steel.

Wastewater containing FOG flows into the GRU, through a filter to remove food particles, then through a baffle system where the FOG separates and rises to the surface. However instead of the FOG building up as it does in passive grease traps, the GRU has a mechanical means of continuously removing the FOG into an external container that can be discarded (or re-used). When the GRU is kept well maintained then it will remove the fat oil and grease and only the cleaner water will flow into the wastewater system. GRUs are very efficient at removing FOG from wastewater.

Considerations

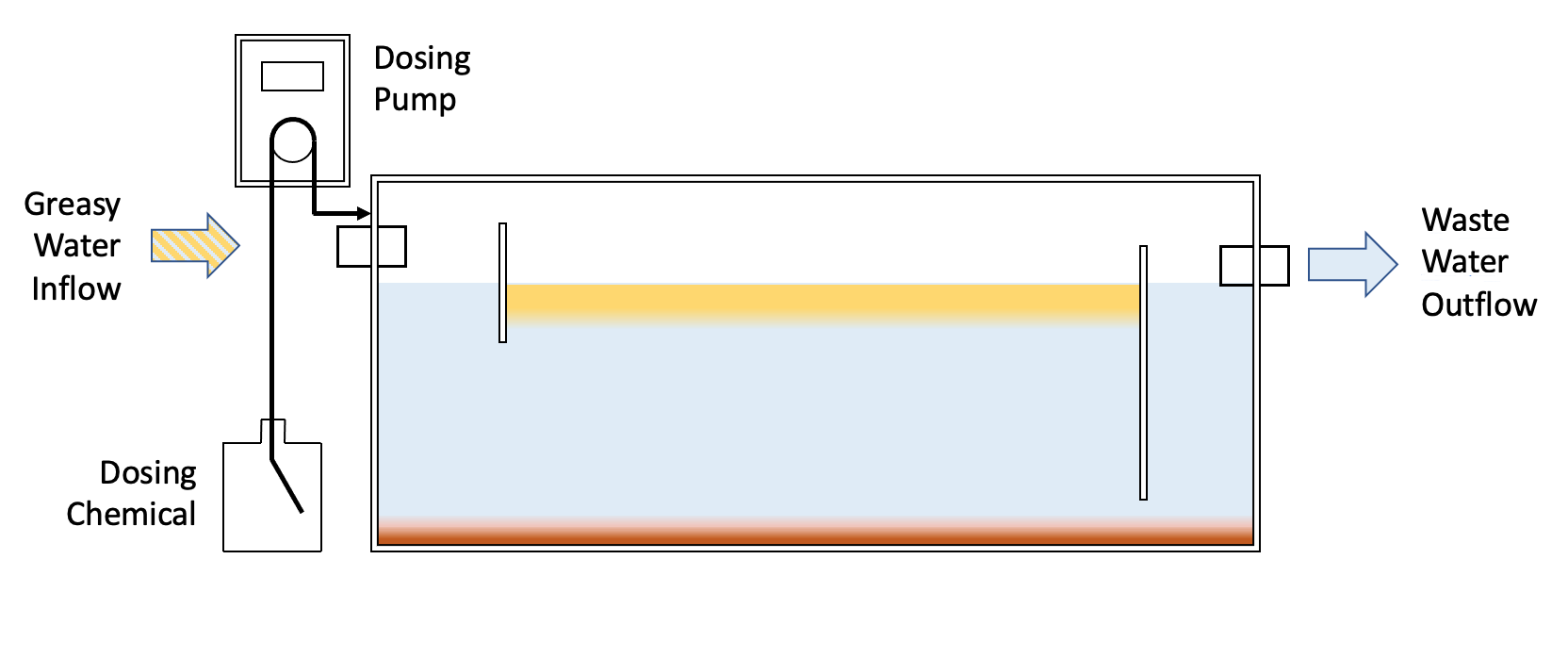

Grease Converters

Grease Converters (MACTRAP Grease Converter ChemiClean) are usually installed internally, under a bench, and close to the sink where the waste water containing the FOG flows out. Similarly to GRU, they are usually made from stainless steel, but polymer versions are available where minimising cost is important. Grease Converters are fitted with an automatic dosing pump which pumps a set amount of bio-enzyme or equivalent into the tank. Wastewater with FOG flows into the trap and this is broken down by the enzyme. The FOG (non-congealing) flows in solution with the wastewater into the wastewater system.

Many councils do not allow these units so you need to check if they are allowed in your area. The reason many councils do not allow these units is because food waste allowed into the grease converter reacts with the bio-enzyme and may stop it working effectively. This means the FOG is not properly broken down before it flows into the wastewater system. However if you are scrupulous about keeping food out of the unit, and ensure the bio-enzyme dosage is set correctly, then they work well.

Considerations

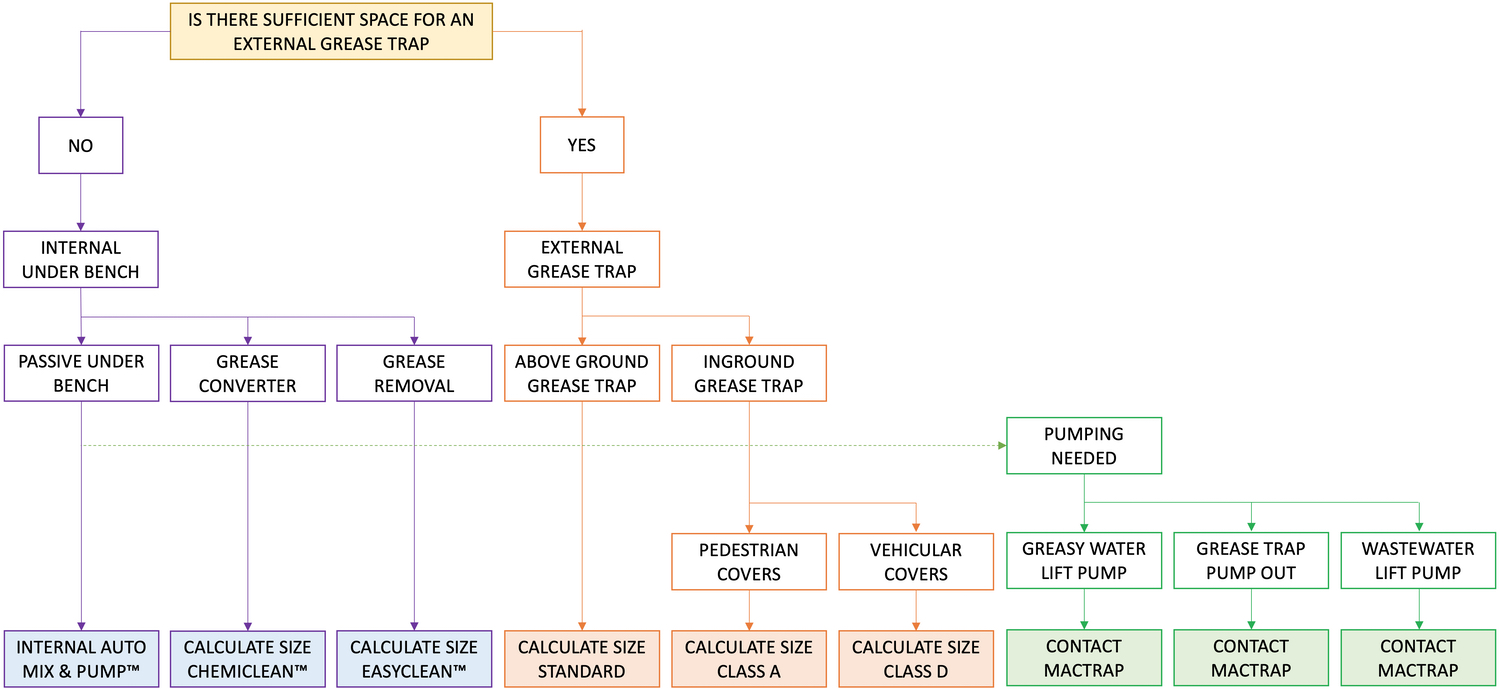

DECISION TREE